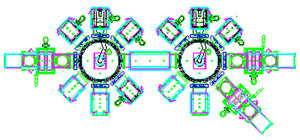

Cluster Tool for Prototyping

Cluster tools eliminate cross-contamination in multi-layer thin film structures and allow the production of high-quality electronic devices. Each MVSystems module as described below is controlled independently allowing simultaneous deposition in all chambers.

Cluster tools eliminate cross-contamination in multi-layer thin film structures and allow the production of high-quality electronic devices. Each MVSystems module as described below is controlled independently allowing simultaneous deposition in all chambers.

Vacuum: High vacuum (HV).

Substrate size: 30cmx40cm.

Modules:

- PECVD: RF, VHF and pulsed (modulated) RF plasma.

- Sputtering (ITO, AZO, ZnON, metals, etc) with oscillation.

- Park station with heating capability

- Isolation and Transfer Zone (ITZ) with robotic arm (8 port locations)

- Load lock with the following options:

- single substrate capability.

- multi-substrate capability.

- In-situ characterization module

- Co-joining of cluster tools allows expansion and higher throughput.

Control: Computer controlled with easy to use HMI and data logging.

Systems guarantees are defined in the contract and include*:

- Base pressure on each chamber

- Temperature calibration

- Uniformity and opto-electronic properties for each material defined in the contract

- Functionality of all systems

* These are demonstrated during the Factory (or First) acceptance test (FAT) and Site (or Second) Acceptance Tests (SAT)